Building Smarter, Faster, and More Affordable Housing

Our mission at Ink Built is to deliver the housing people need and deserve to meet their basic needs no matter where they are on the economic spectrum.

We strive to do this at every scale with a focus on affordability, sustainability, and efficiency; because the need is immense, and our industry has not been able to keep pace. We’ve designed our practice, and tuned our focus to address this challenge at every level.

the modular advantage

The promised cost savings of offsite construction have been touted for decades, but adoption has remained slow for a variety of reasons, and limited to certain building types and situations.

Today, however, we feel that its advantages are solidifying in the Northwest regional market for many project scenarios and scales.

We witnessed this first-hand on our Breitung Building project which delivered below market cost, and came together smoothly in construction with very few issues and limited work required on site.

Comparing that with the long durations and challenging, unpredictable construction process we’ve seen on many conventionally-built new-construction projects, we decided to get curious and have been diving deeper ever since.

The project was constructed in twelve months with a minimal crew, and final cost $30/sf less than typical market in 2019.

THE TIMES HAVE CHANGED

Today, however, its advantages are solidifying thanks to changing conditions in the northwest regional market for many project scenarios and scales.

Working in partnerships to find clearer insights to the barriers around modular implementation, challenges that projects have faced, and what can be addressed in the design and delivery process; our understanding has become clear, and some specific solutions and support we can offer to our clients and collaborators to actually realize the potential advantages of modular project delivery have begun to emerge....

this comes just as the construction industry has begun to feel the significant shortage of qualified subcontractors, making project delivery expensive and unpredictable.

The fundamental key to success is to approach modular project delivery as a paradigm shift rather than a minor adjustment to traditional development and construction processes; and it requires buy-in from developer, architect, and contractor from day 1.

MODULAR IS THE MOST EFFECTIVE TECHNOLOGY TO OPTIMIZE CONSTRUCTION EFFICIENCY

-

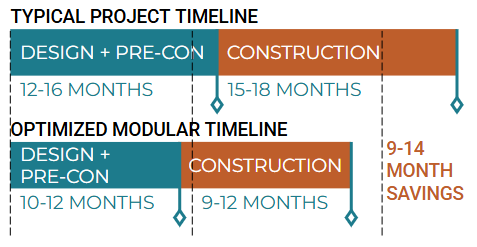

The potential to achieve a year or more reduction in project delivery means:

Less risk / exposure to market changes

Better access to competitive funding opportunities

Lower management / overhead labor required

Loan interest savings- Quicker investor payback

Greater overall capacity / throughput for your organization

Pre-designed prototypes provide even more opportunity to reduce design, permitting, and contracting time

-

Modular manufacturer pricing tends to remain far more stable than typical market, with slower & steadier rate of change.

Manufacturer pricing is predictable as it is based on a constant flow of similar projects (especially so with pre-designed prototypes).

Cost savings are possible through a number of avenues:

reduced GC overhead / management / time on site

less exposure to prevailing wage impacts- more efficient factory labor

more stable and consistent material sourcing

avoidance of weather and other site related delays

opportunity to use smaller, less

sophisticated subcontractors

-

The potentials to reduce risk exposure for projects and improve outcomes are numerous:

Predictable capacity & delivery timeline with less potential for unforeseen issues, weather delays, etc

Consistent processes and conditions in the factory yield consistent results

Reduced exposure to market changes, finance costs, etc

Improved site safety and reduced congestion on site

Less pollution and reduced impacts to neighbors

Predictable delivery and capacity in almost any market and site location from tight urban space to remote rural locations

Less wear & tear, damage, rework, and touchup throughout construction

Improved acoustic privacy

Reduced waste

Reduced embodied carbon emissions

Opportunities to improve energy efficiency with lower first cost impacts

-

What about the real challenges?

If it’s so great and it’s been around, why haven’t more projects been built this way?

I’ve heard horror stories….

Why aren’t more GC partners eager to use it?

I / others have priced it, but it hasn’t come in cheaper yet….

I can predict the typical challenges of construction, why introduce new ones?

These are legitimate; and, there are answers. Like all construction projects, many variables are at play, and not every answer is applicable to every project. But you should ask them, and not pursue modular construction for yourproject without satisfying strategies that address these questions.

Efficient modular buildings have more constraints, and require more strategic thinking to capture efficiencies and benefits. Our approach considers these issues at every level: from design, to permitting, to factory production, shipping, and site contractor handoff.

A Groundbreaking Partnership

One of our deep dives into modular construction has led to an incredible partnership with Blazer Modular Construction. We partnered with them to apply for the State of Oregon’s Modular Housing Development Fund, which awarded them a $5M grant to work on increasing housing production capacity through modular construction.

Blazer’s visionary leadership focused this investment on partnerships with a number of experts in design and construction, enabling us to look at many fundamental challenges for housing production and modular construction.

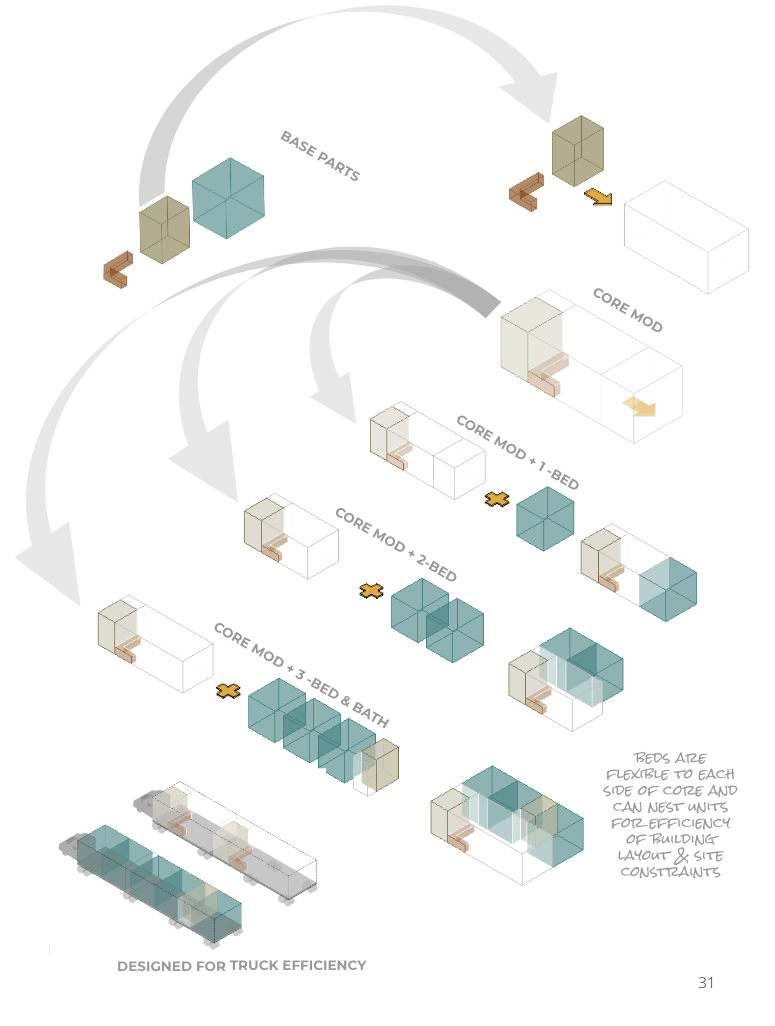

Our scope of work allowed us to create a set of middle housing prototypes that align with the State’s recent focus on land-use policies to enable this housing type, and are able to be rapidly implemented in communities across the state.

MODULAR PROJECTS CURRENTLY UNDERWAY

These projects are currently in the development process and are leveraging the potentials of modular construction to provide rapid housing solutions that are net-zero ready, and designed to address culturally-specific needs through flexibility and cost-effective project delivery.

Affordable Cooperative Housing for BIPOC Families

Affordable Family-Size Townhomes in a new urban neighborhood with accessibility for aging-in-community (rental + homeownership)

Affordable Homeownership for BIPOC Families

Check back here for more details and examples soon to come, and to see additional housing options including:

Culturally-specific prototypes for Native Tribes

Transitional Housing prototypes for co-living and village pods

Multi-family units for 3- to 6-story buildings of any size that can be assembled in many configurations to meet real site constraints and project requirements

Flexing with Site Conditions

Housing that enables more homes to fit on a given site / neighborhood, while still providing the quality of life that many desire in single-family homes such as ample space, daylight, and access to outdoor space. Our Middle Housing Prototypes can be implemented in most local zoning across the state.

READY TO MAKE A PROJECT THAT IS DELIVERED FASTER, SMOOTHER, MORE COST EFFECTIVELY, & WITH LESS RISK?

We understand that modular delivery isn’t a magic solution for every project, and that there’s no substitute for an excellent general contractor. Successful implementation requires the same level of focused attention to design and construction planning as any typical project, if not more so, and requires a strong willingness to adapt mindsets to work with it as its own unique methodology with its own fundamental constraints and opportunities.